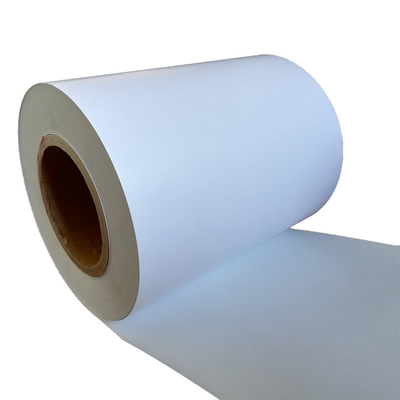

HM2233 Top Thermal Paper Adhesive Label Material with White Glassine Liner

Product Details:

| Place of Origin: | China |

| Brand Name: | Superreliable Technology |

| Certification: | ISO |

| Model Number: | HM2233 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 4000SQM |

|---|---|

| Delivery Time: | 10 Days after order confirmation |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

|

Detail Information |

|||

| Facepaper: | Top Coated Thermal Paper | Adhesive Glue: | Rubber Based Hotmelt Glue |

|---|---|---|---|

| Liner: | White Glassine Liner | Contact Number: | 8615653609093 |

| Contact Email: | Tiger@superreliable.cn | Contact Person: | Tiger Huang |

Product Description

Item: Top Thermal Paper/HM Adhesive/Glassine Liner

Key Features:

> Very good barcode printing performance

> Top coated protection layer

> Very good moisture, scratch resistance,chemical resistance.

> Suitable for mid & short term label applications, like price tag and logistic label

Facestock

Top coated thermal paper,White, woodless paper, treated with black heat-sensitive coating, has resistance to water, fats, oil, lubricant, alcohol and many solvents

Basis Weight: 70gsm± 10%

Caliper: 0.070mm ± 10%

Adhesive

HM Model. A general purpose permanent, rubber based adhesive.Suitable for high speed die cutting and auto labeling

Liner

A super calendared white glassine paper with excellent roll label converting properties.

Basis Weight: 60GSM Color: White, Yellow, Blue

Caliper: 0.050mm

Performance data

Viscosity: 10000-11500 180°Pealing Streagth: 24N

Innitial Tack: 36N or ball No 28 Hold Tack: More than 72 Hours

Minimum Labeling Temperature: 5℃

After Labeling 24Hous,Service Temperature Range: -20℃~50℃

Applications and use

This thermo sensitive product is designed for weight scale printing and medium low speed thermal barcode printing and logistic label.

Exposure to sunshine or above 50°C should be avoided. It’s not suitable for curve substrates.

Not recommend on the PVC substrate.

Conversion/printing

This product is suited for all the usual printing technologies. Due to the thermal sensibility, in the process material temperature should not more than 50℃.

Excellent conversion characteristics in rotary and flat-bed

Shelf life

One year when stored at 23 ±2°C at 50 ±5% RH.

![]()